Hyosung Chemical: Evolving into Market-Driven Company

品牌新闻

Apr 05, 2024

As health awareness increases, the choice for Zero Sugar over regular Coke has become more prevalent. Various Zero Sugar products can now easily be found in convenience stores. The market-driven strategy is about identifying customer needs and following market trends. Market-driven companies create new markets and manufacture products based on understanding of their customers, similar to the company that first launched Zero Sugar. In the past, businesses created products first and then hoped customers would choose their products. However, they now need to anticipate customer needs and make what is desired. The shift in focus from quantity to quality in a market-driven strategy is important, where customers choose what they want. It’s now crucial for companies to pay attention to customers’ voices.

Hyosung Chemical’s Daily Products

Hyosung Chemical manufactures a variety of chemical products across various industries. The most representative product is Polypropylene (PP), a type of plastic resin. Without realizing it, we have been using Hyosung Chemical’s products daily, as the company manufactures materials for plastic for disposable cups, plastics for kids, and films for food packaging. It is no exaggeration to say that Hyosung Chemical is critical in facilitating our lives convenience. With its advanced technology and products, Hyosung Polypropylene holds the largest market share in Korea. TPA, known for its superior quality, is exported to Asia, Europe, and the Middle East. Hyosung Chemical is the first company in the world to successfully commercialize Polyketone (POKETONE), a new and eco-friendly polymer material. Nitron Fluorine Three is essential for the cutting-edge electronics industry, while TAC film, used for packaging, industrial applications, and optical science, has made the localization of electronic materials possible. As the importance and interest in environmental issues continue to rise, Hyosung Chemical has been striving to establish a sustainable management system by developing eco-friendly materials and innovating manufacturing processes.

Hyosung Polypropylene with the Global Competitiveness

Hyosung Chemical has been manufacturing and supplying polypropylene (PP), the most widely used general-purpose resin. Hyosung’s PP is exported to countries around the world and used for variety of applications, including water supply pipes and plumbing, medical fluid and syringe, transparent food containers, special films, car interior and exterior materials, and heat-resistant home appliances such as toaster or kettles. The success of Hyosung’s PP/DH PU is largely due to the company’s vertical integration from materials to final products, which ensures stable manufacturing. Thanks to Propane Dehydrogenation (DH), its ability to supply its high-purity Propylene contributes to a stable supply and excellent technologies skills, enhancing its competitive edge.

Hyosung Chemical’s the most common polypropylene (PP) products is transparent and airtight food containers. These containers are popular due to their transparency, allowing easy identification of the food inside. Concerns often arise that the container might break if it contains too much liquid or if the weather is too cold. In response to these concerns, Hyosung invented a ‘random block’, a new type of PP that boasts excellent shock resistance and transparency. Hyosung offers two kinds of PP; random copolymer, which is transparent, soft, shock resistant, and free of harmful materials, and block copolymer, which has an excellent balance between high stiffness and shock resistance. Random block combines the advantages of both types. It is used for containers for shampoo or food, boasting high shock resistance and strong resistance to low temperatures, preventing any damage in the freezer. This is another example of Hyosung’s market-driven approach, identifying customer needs, enhancing the products, and developing the technology.

TPA to the Global Market

TPA (Terephthalic acid) is the crucial ingredient in high-functional polyester used for tire cords, plastic bottles, and polyester film. . Leveraging its extensive know-how and state-of-the-art facilities, Hyosung Chemical produces and supplies 420,000 tons of high-purity TPA annually. This high-purity TPA is utilized in high-functional polyester, tire cords, and polyester film and is exported to countries across Asia, Europe, and the Middle East, enhancing the respective manufacturers’ competitive edge.

Hyosung’s Films in Daily Lives

Hyosung Chemical manufactures diverse range of nylon and polyester films, which are utilized in various applications, including films for food, detergent, medicine packaging, interior and exterior car components, building windows, advertising banners, and sheets for furniture or electronics. Hyosung Chemical’s TAC film, used as a protective layer of LCD screens in TVs, monitors, and laptops, has managed to break into the broad Chinese market, which is currently the largest in the display sector. The company continues to invest significantly in this area, aiming to develop new film types and penetrate various optical film markets.

Additionally, Hyosung Chemical produces films and polyketone for electronic cars and foldable phones. Blue license plates have become a common sight, drastically increasing the number of electronic vehicles. These cars require a secondary battery compromising four core components: anode material, cathode material, separation membrane, and an electrolyte. Hyosung has been manufacturing PET separator membranes designed to halt the movement of lithium ions by blocking pores, thereby preventing short circuits when the battery overheats. They also produce a NY film for cell pouch of secondary batteries. Anticipating the growing demand for NY films, Hyosung Chemical has developed the appropriate technology to cater to electric vehicles.

Hyosung Chemical also supplies important parts for foldable phones with retardation PET films to protect the internal and external LCD. It also manufactures eco-friendly PCR film, which safeguards products during shipping. As these products continue to grow in popularity, Hyosung aims to consolidate its market presence by anticipating customer needs and developing the necessary technologies accordingly.

NF3 Gas, Hyosung’s Own Industrial Specialty Gas

Hyosung Chemical manufactures industrial specialty gas, NF3 Gas, used to cleanse the surface of semiconductor, displays, and solar modules of foreign materials. Neochem PU, founded on Hyosung’s unique know-how and high-quality technology, commenced manufacturing, production, and sales of on-spec products in a short time after the completion of the plants in 2007. In response to the expanding semiconductor and display markets, it has progressively broadening its manufacturing lines to establish a robust supply system.

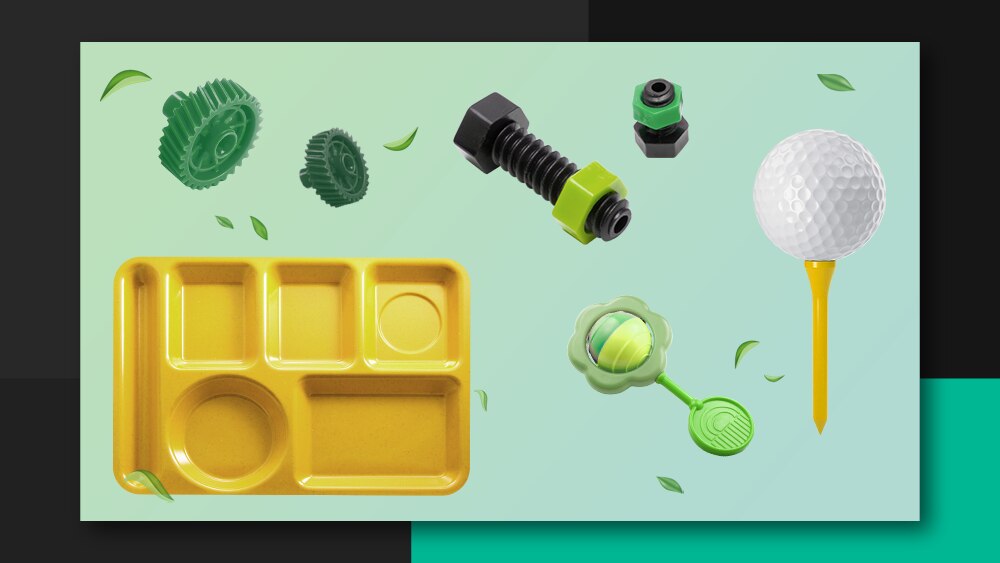

POKETONE, Eco-friendly New Material

Hyosung Chemical acknowledge its responsibility for environmental issues due to petrochemical technology and has been proactive in combating climate change by fostering a virtuous cycle of resources with eco-friendly products and technology. It became the world’s first company to develop POKETONE, an eco-friendly plastic that effectively reduces carbon emissions. As climate change remains critical topic in eco-friendly market, POKETONE is gaining popularity for its lower CO2 emissions, in sync with global zero-carbon trend. Its superior properties can also improve energy efficiency. With high impact resistance, chemical resistance, and wear resistance. POKETONE has seen wide-ranging applications. Certified by various entities, including the U.S. FDA, it has been safely used for food containers, children’s toys, and medical parts since 2016 due to its non-toxic nature. In 2020, it was applied to water meters in Seoul. POKETONE received an eco-friendly certificate from the Ministry of Environment for contributing to carbon emission reduction through its extensive use in gears, vacuum cleaners, cars, and connectors. In alignment with the global eco-friendly trend, Hyosung Chemical strives to develop and apply new environmentally conscious materials.

A Step toward Hydrogen Society, Liquid Hydrogen

Hyosung Chemical is actively participating in the global efforts to find and commercialize clean energy sources that could replace fossil fuels to protect the planet. The company is striving to build a hydrogen ecosystem in Korea to revitalize hydrogen economy, including liquid hydrogen production. While Hyosung manufactures polypropylene for plastics, it generates about 12,000 tons of byproduct hydrogen annually. This hydrogen is planned to be supplied to hydrogen fueling stations for cars managed by Hyosung. To this end, Hyosung partnered with the Linde Group, a global chemical company renowned for its advanced liquid hydrogen technology. The goal is to construct the world’s largest single liquid hydrogen plant. This initiatives signifies Hyosung’s commitment to laying the groundwork for creating hydrogen value chains through the manufacturing and supply of liquid hydrogen. The liquid hydrogen produced by Hyosung Chemical will be transported in carbon fiber containers made by Hyosung Advanced Materials. It will then be supplied to hydrogen fueling stations built by Hyosung Heavy Industries, fostering a nationwide fueling system for hydrogen cars. This indicates Hyosung’s efforts to nurture a hydrogen society in Korea.

We encounter Hyosung Chemical’s technology daily, from materials for smartphones and laptops to packaging for food and beverages. By leveraging Hyosung Chemical’s superior technology and know-how, these products can effectively address the megatrends of climate change and environmental protection. This is due to Hyosung Chemical’s active consideration of eco-friendliness and its continual research and development of relevant products. Eco-friendliness is an enduring trend and a core value that will persist. Hyosung Chemical will continue to enhance its research and development efforts to transform into a sustainable company with future-ready technologies.