Trendy, Hyosung! Chemistry

品牌新闻

Apr 11, 2024

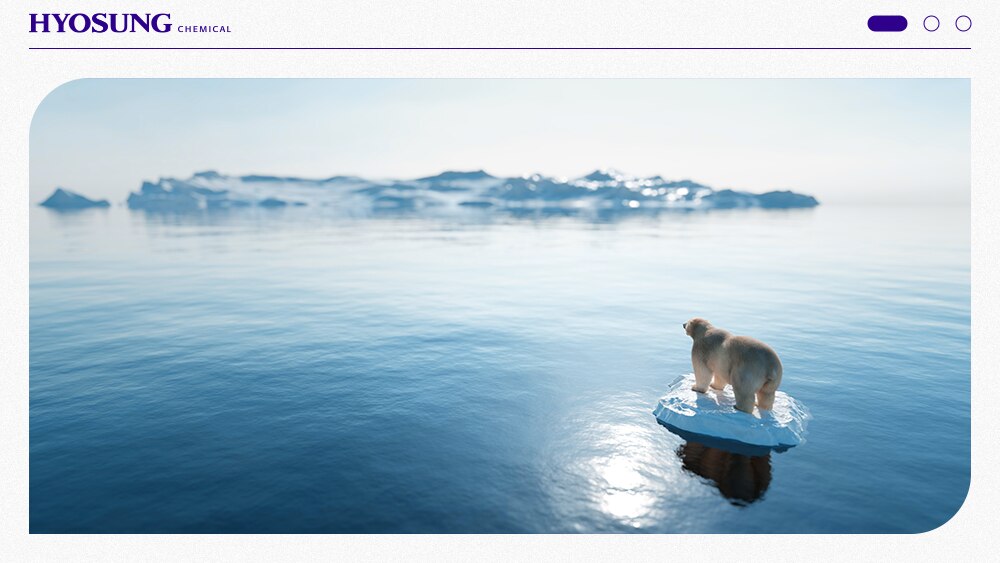

Global warming due to the greenhouse effect is raising awareness across the globe. The repercussions of climate change, such as glacial shrinkage, desertification, and accelerated sea-level rise, are manifesting more than ever, with severe weather anomalies escalating. South Korea is no exception, suffering from weather irregularities and ecological shifts, marking it the most pressing environmental issue we face today. The ongoing COVID-19 pandemic has exacerbated the situation, with the surge in delivery food services causing a drastic increase in the use of plastics and disposables, leading to an escalating waste issue.

We've moved beyond the era where environmentally friendly activities were a personal choice and now stand at the onset of an era of necessity—an era where preserving our planet for future generations is imperative. People have begun to recognize the importance of sustainability over convenience and acknowledge the need to cease actions that destroy nature for human convenience.

As environmental consciousness becomes a trend, it has become apparent that we need chemical technologies that consider the environment as a priority in the production of various consumer goods. These range from single-use cups, tumblers, cosmetics, toys, and electronic products that we use every day, to electric vehicles—a testament to the urgency of sustainability.

The Transition to 'Necessitated Environment' in Plastic Usage

Plastic is being used everywhere around us, often without our awareness. Plastic is found in many everyday items, including plastic cups and tumblers we use without thinking. It also used in cosmetics, children's toys, household items, and electronic products. We have to deal with omnipresent plastics daily, refusing to return to nature with time and degrading into microplastics, negatively impact human health, the environment, and our lives.

The need for change is spreading across the plastic industry, known for contributing to environmental pollution and ecosystem disruption. Since awareness about the environment shifts has shifted, and environmental necessity is becoming a trend, concerted efforts have been made to discontinue the use of plastics daily. In addition to finding alternatives to plastic, it is not easy to stop using it immediately, given its deeply ingrained presence in daily life. Through its technological capabilities, Hyosung Chemical aims to fill the void left by plastic by preventing environmental harm and facilitating resource circulation.

The need for change is spreading across the plastic industry, known for contributing to environmental pollution and ecosystem disruption. Since awareness about the environment has shifted, and environmental necessity is becoming a trend, concerted efforts have been made to discontinue the use of plastics daily. In addition to finding alternatives to plastic, it is not easy to stop using it immediately, given its deeply ingrained presence in daily life. Through its technological capabilities, Hyosung Chemical aims to fill the void left by plastic by preventing environmental harm and facilitating resource circulation.

Hyosung Chemical: Crafting Thoughtful Plastics for the Environment

Understanding that we cannot immediately cease the usage of plastics, now a prime perpetrator of environmental pollution, Hyosung Chemical has dedicated its efforts to create a virtuous cycle with the plastics already in existence. In addition, Hyosung Chemical has pioneered eco-friendly alternatives to the countless consumer goods currently reliant on traditional plastic. In 2013, Hyosung Chemical developed the world's first eco-friendly plastic material, POLYKETONE, and through the use of PCR PP and PCR PET FILM technologies, Hyosung Chemical not only creates non-harming plastics but also breathes new life into the plastics already in use, creating a circle of resourceful sustainability.

The environmentally friendly new plastic material, POLYKETONE, developed by Hyosung Chemical, is manufactured using carbon monoxide, ethylene, and propylene, which are among the main culprits of air pollution. This innovative process utilizes carbon monoxide generated from factories, thus not only reducing carbon emissions with each production but also playing a role in diminishing environmental pollution. Moreover, its superior functionality allows it to be applied in various fields.

First and foremost, Hyosung Chemical's POLYKETONE is free from harmful substances, making it suitable for food-related applications. It demonstrates superior durability, outlasting conventional materials even when regularly exposed to disinfectant sterilants. Boasting chemical resistance and high gas barrier properties, it's employed in various extrusion applications, including mining pipe liners and food-grade films. Its resistance to impact and wear contributes positively to the industrial materials' lifespan enhancement. POLYKETONE remains unchanged even when exposed to chemical substances like fuel and coolant, and its excellent insulation makes it suitable for automobile parts, thus finding application in a multitude of components.

The Cycle of Plastic, PCR PP

Just as crucial as the development of new materials is the handling of plastics that have already served their purpose. Plastics, which break down into microplastics instead of disappearing, disrupt the ecosystem and find their way into our food chain. Hyosung Chemical has focused on creating a recycling cycle for used plastics to prevent their degradation into microplastics, which pose a threat to our health and environment. The champions of this initiative are PCR (Post-Consumer Recycled material) PP and PCR PET FILM, which are produced by recycling plastics discarded after use.

Polypropylene (PP) is a widely-used plastic, featuring in everyday items like cups, straws, and lunchboxes. Renowned for its excellent durability, it enables long-term usage, and its lightweight, smooth, and transparent properties make it a versatile material. Hyosung Chemical transforms this commonly used PP back into a raw material—PCR PP—through a mechanical recycling process that involves grinding, washing, and melting it back into pellet form.

Similarly, PCR PET FILM contributes to the virtuous cycle of plastics. This recycled film is made from used PET and is used in IT mobile outgo protection films, label films, and more. Hyosung Chemical manufactures its PCR films using a 3Layer process, containing over 99% eco-friendly raw materials, earning it RCS certification. Hyosung Chemical has also developed environmentally friendly silicone films using recycled chips, signifying Hyosung Chemical's commitment to environmental considerations from the development stage.

Transitioning Towards a 'Necessitated Environment' Stance, Rechargeable Batteries

In the midst of a transition to an environment of necessity, the energy industry is garnering increased attention. With the rise in environmental consciousness, electricity and similar forms of energy storage, as well as their usage, are gaining immense popularity. There are significant transformations underway in the power storage market.

Our modern technological civilization is hindered by the challenge of secondary batteries, to the extent that the miniaturization of high-performance secondary batteries has become a crucial issue in technological advancement. The potential for growth is high, with the development of compact high-performance electronics and lightweight electric vehicles now within reach.

Hyosung Chemical is involved in the production of the separator, a component that plays a crucial role in battery stability, lifespan, and high-speed charging. This component is among the four key materials found in secondary batteries. Hyosung Chemical produces PET separators that prevent the movement of lithium ions and hinder battery short-circuiting by closing their pores when the battery temperature exceeds a certain level.

Additionally, Hyosung Chemical manufactures NY films, which serve as the exterior material for lithium polymer secondary batteries. The NY films produced by Hyosung Chemical are located on the outermost layer of the cell pouch, and they play a vital role in electric vehicle manufacturing due to their superior pinhole resistance and formability.

The film technology of Hyosung Chemical is not limited to secondary batteries for electric vehicles and cell pouches. It can also be found in commonly used foldable phones. The films that protect the LCD screens of foldable phones, both externally and internally, are produced by Hyosung. Hyosung produces a low-shrinkage PET film and eco-friendly PCR film for mobile shipment protection.

The invention and advancement of plastics have rendered our lives convenient, enabling us to procure a variety of everyday items at a more affordable cost. However, this convenience has been attained at a high price, resulting in various health hazards and environmental pollution that now threatens our very existence. As we move beyond the era of environmental friendliness to one where environment protection is a necessity, what we need more than ever is a sustainable alternative to plastic.

Understanding that it's not immediately feasible to stop using plastics, materials that have contributed immensely to human convenience, Hyosung Chemical, with a deep understanding of environmental concerns, has developed POLYKETONE, a new material that can substitute plastics while preserving the environment. Hyosung Chemical has developed technologies to recycle already manufactured plastics into PCR PP and PCR PET FILM, ensuring that these materials do not pose a threat to humanity and can circulate safely.

We are acutely aware that, unless we reclaim more plastics from production processes and the seas, and unless we develop more eco-friendly raw materials, we will not be able to secure our cherished daily lives and a bright tomorrow. The industry is transitioning from merely producing chemicals to protecting, improving, and creating innovative solutions for future generations.

Hyosung Chemical is committed to protecting our radiant daily lives and creating 'The Next Chemistry' for future generations. This means striving to reduce carbon emissions, discovering and manufacturing materials that closely adhere to natural laws, and continually advancing our technological capabilities.