Closed-loop Recycling

Closed-loop recycling policy

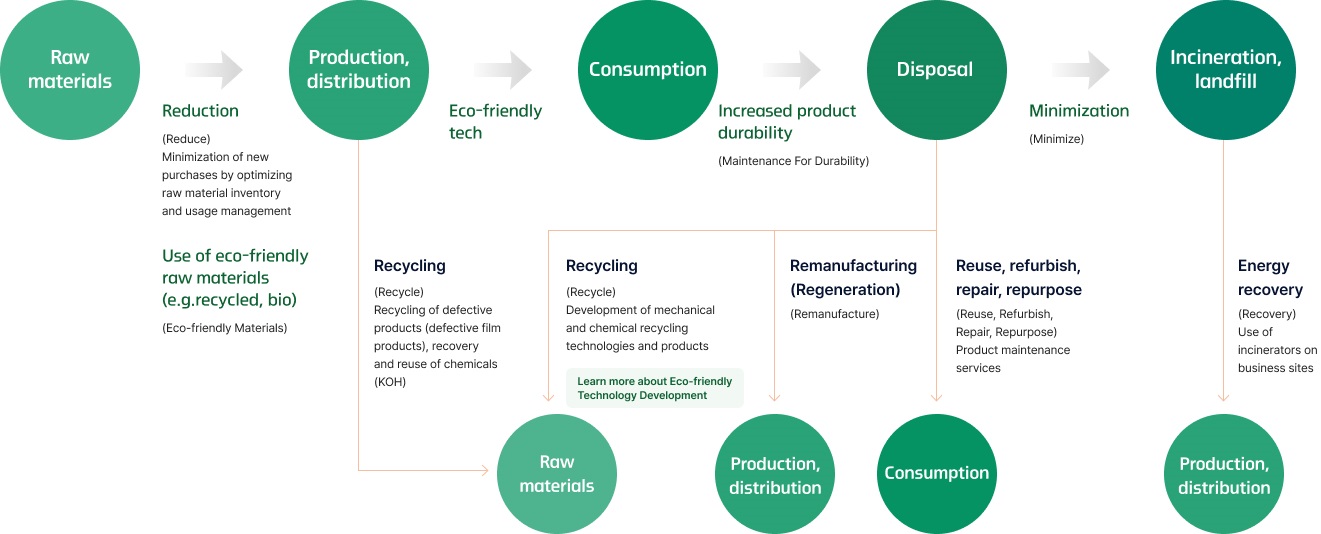

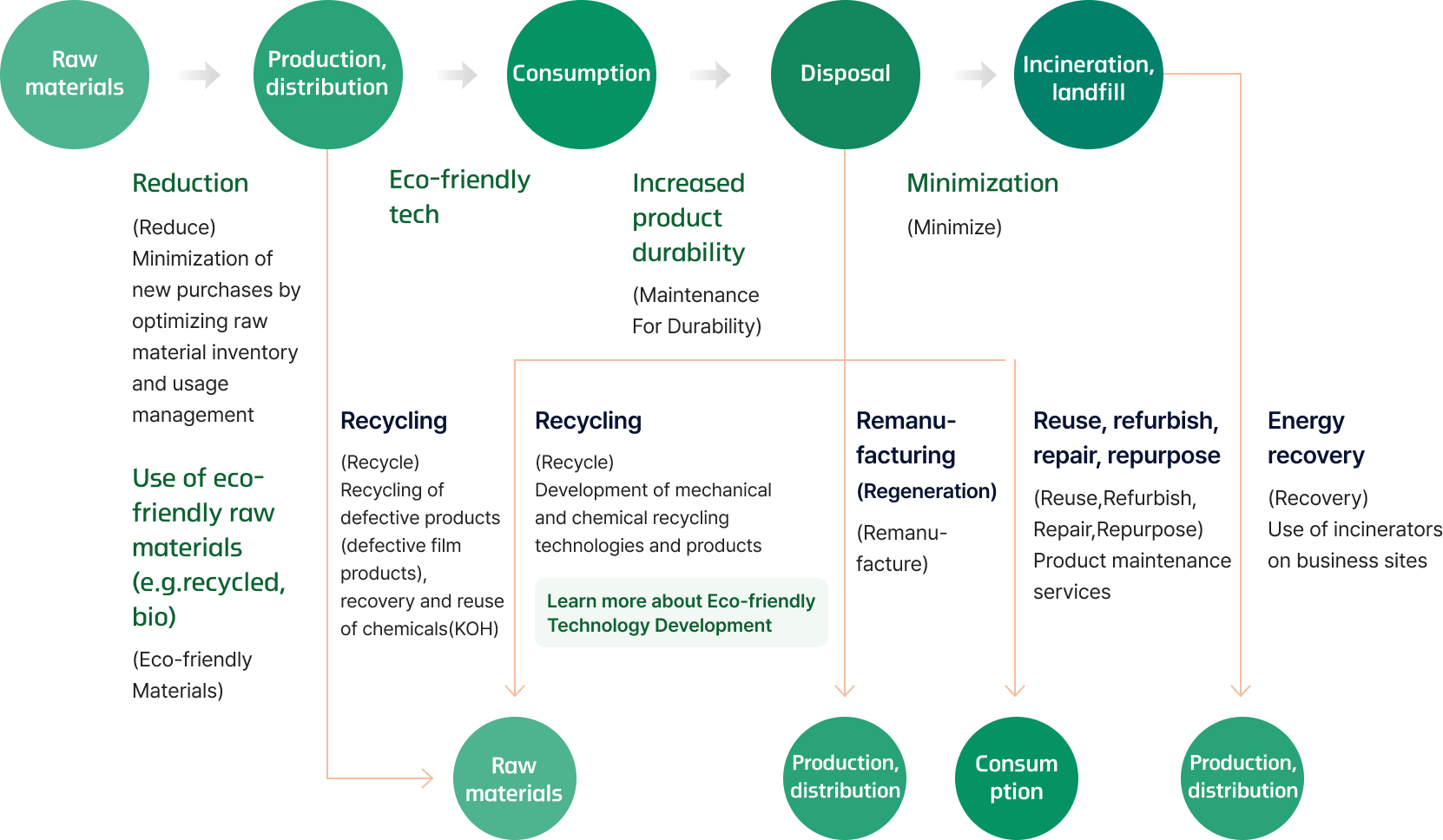

Hyosung Chemical employs a company-wide approach to closed-loop recycling as part of our efforts to preserve the earth's resources for coming generations. We contribute to building a sustainable circular economy and society by promoting the closed-loop recycling of waste. We maximize the efficient use of resources throughout the production, distribution, and consumption processes, and we establish and implement policies at each stage to contribute to the development of a circular economy and society by reducing waste generation.

Eco-friendly waste reduction activities

for closed-loop recycling

-

01

Activities to reduce the use of raw materials and water resources

We reduce the amount of new purchases by optimizing the inventory and usage management of raw and auxiliary materials. We conserve water by minimizing unnecessary water use in the production process. Each year, we set water consumption targets for each water source, such as municipal water and industrial water, and work to reduce the amount relative to targets.

-

02

Products produced using recycled PP

Hyosung Chemical has acquired GRS certification for 30%, 50%, and 100% recycled PP. GRS certification is a certification that demonstrates the use of recycled raw materials in the production of PP goods. Utilizing recycled raw materials, we participate in international efforts to reduce resource consumption.

-

03

Purchasing eco-friendly products considering resource conservation

In consideration of resource conservation, Hyosung Chemical adheres to a green procurement policy and continues to engage in eco-friendly procurement.

-

04

Closed-loop recycling through waste treatment and recycling

In order to reduce waste generation and promote closed-loop recycling, Hyosung Chemical recycles defective film products produced at its business sites as raw materials.

-

05

Development of recycled products and technologies

Globally, companies that manufacture and use plastics are obligated to increase their environmental responsibility by, for example, expanding their scope of responsibility to include the stages of production, use, and disposal. Hyosung Chemical, recognizing the need for a preventive response, devised a plan to replace disposable plastic products with reusable PP containers through external consulting. We plan to invest KRW 500 million in a pilot project in 2022. We anticipate that the project will lead us to establish a business model for plastic recycling in the future and to make action accordingly.

Learn more about Eco-friendly Technology Development -

06

Donation to the first Hyosung Goodwill Store

Goodwill Store is a social enterprise that takes into account "people, businesses, and the environment." It operates approximately 2,800 stores in 15 countries, including the US and Canada, and provides over 200,000 jobs for persons with disabilities and vulnerable groups. Goodwill Store promotes a virtuous cycle of resources by employing the disadvantaged, contributing to economic independence, and using the proceeds from the sale of donated items to create jobs for persons with disabilities and provide vocational training and education. In October 2013, Hyosung opened the first Hyosung Goodwill Store in Eunpyeong-gu, Seoul, a first for a Korean company, and Goodwill Store donation boxes are installed at the Hyosung headquarters and each business site to forward employee donations to the Hyosung Goodwill Store.